Space Structures GmbH is part of the consortium responsible for developing the internal secondary structures for the International Habitation Module (IHAB).

Discover missions in which

our solutions were used

We create the structure backbone for space missions across the solar system for ground tests, launchers, satellites, space stations, lunar and planetary landers and even interplanetary probes. Discover each mission and learn about our solutions.

Chose the distance to downselect:

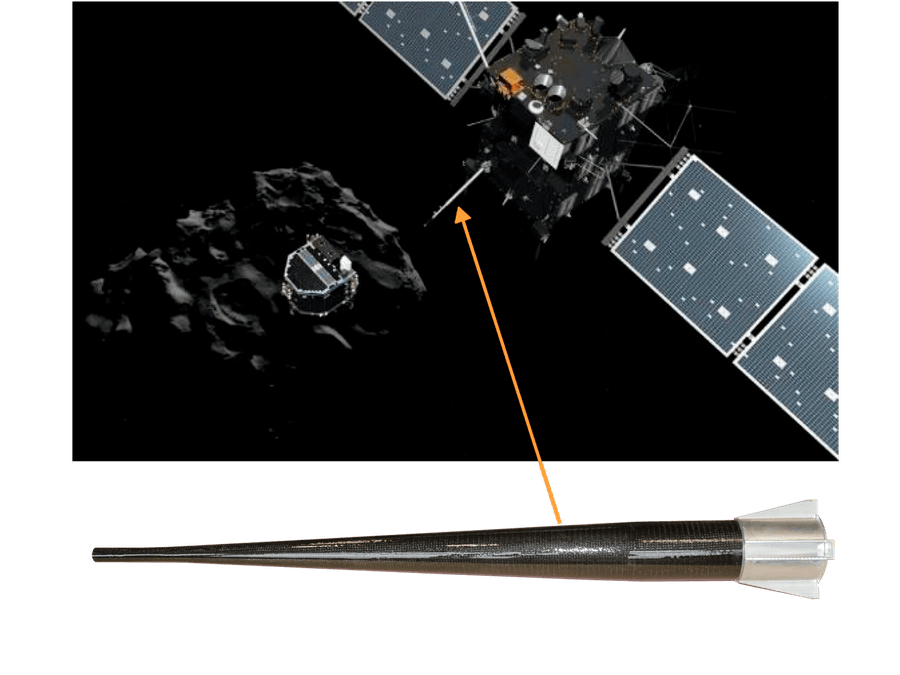

Space Structures GmbH team manufactured a CFRP boom implementing an innovative fiber placement application. The boom was infused using a tailored CFRP fiber placement, ensuring a constant thickness of the item across various geometries throughout the entire length of the part.

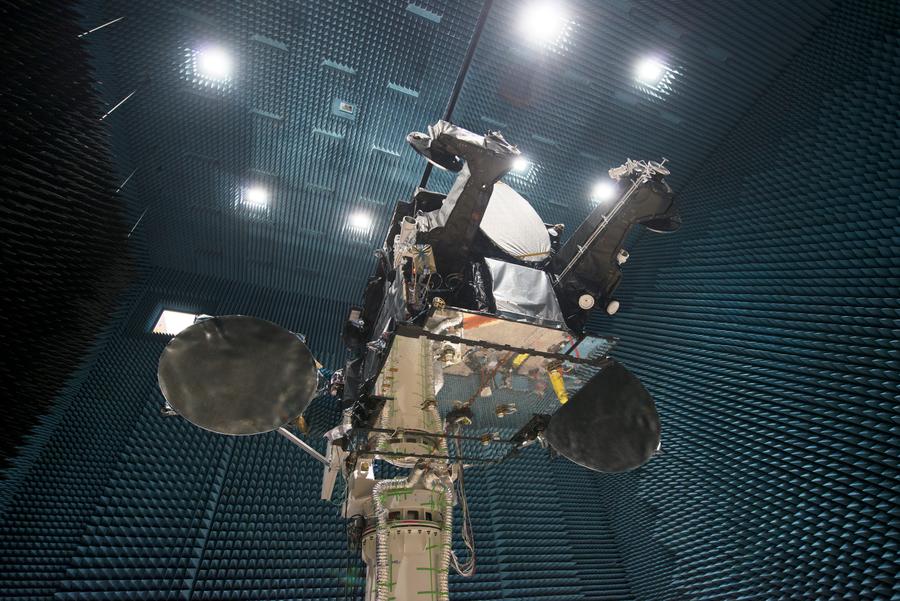

Space Structures GmbH team was responsible for all mechanical aspects of the project on system level.

Space Structures GmbH was responsible for the primary structure cleats as well as the hoisting configurations verification.

Space Structures GmbH team was responsible for the sizing of the primary structure as well as engineering work for several instruments.

Space Structures GmbH performed the complete structural subsystem analysis and verification as part of the consortium with OHB Italia S.p.A., APCO Technologies SA and Sener Aerospace & Defence. In addition we did engineering work for several equipment of the BIOMASS mission.

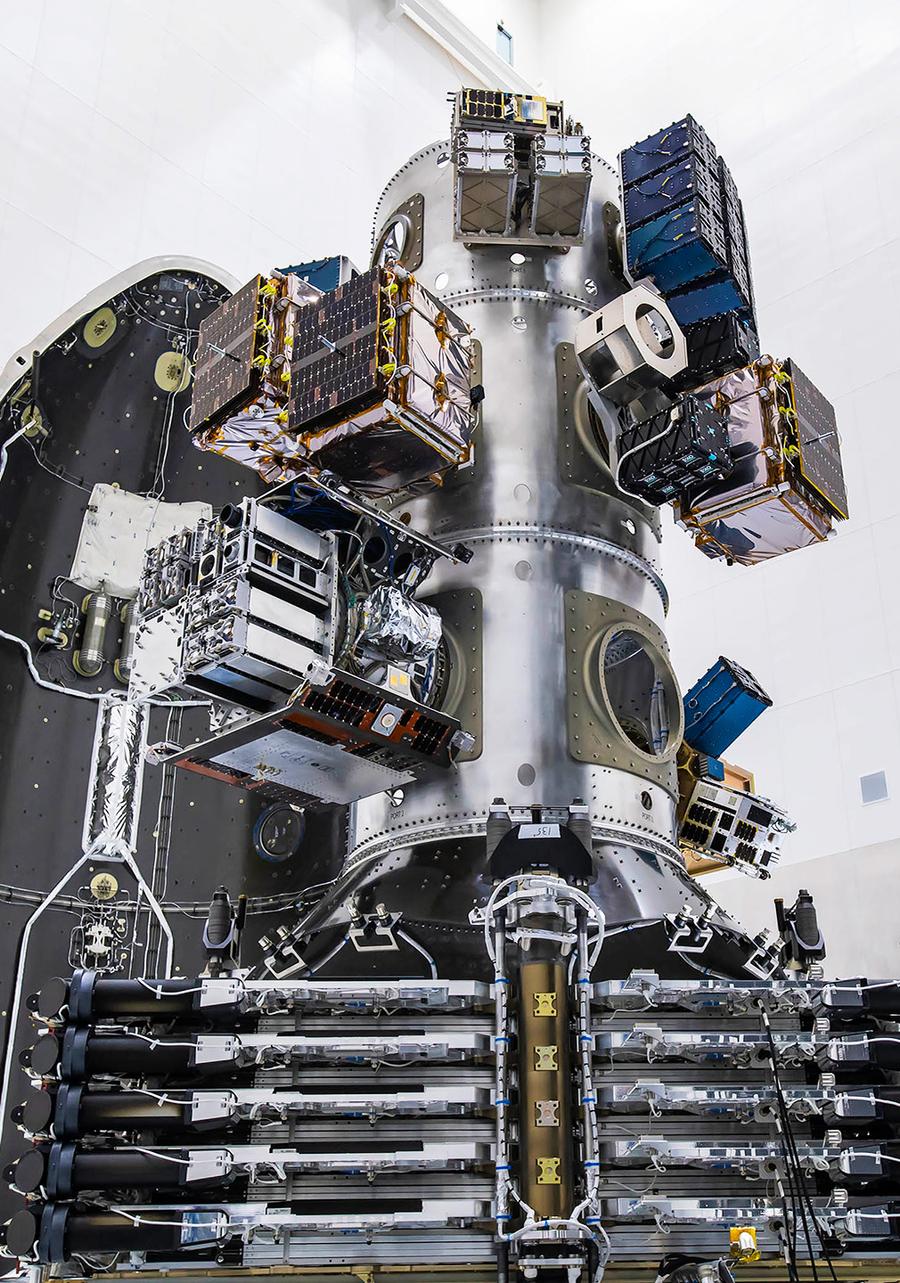

Space Structures GmbH has designed and manufactured rideshare multi-payload adapters for SpaceX Transporter Missions 1 to 7. More than 100 satellites have been launched on our LVA family.

In coopeartion with EOSOL, Space Structures GmbH has developed the complete structure subsystem of the (sub)mm Validation Standard Antenna (VAST) for ESA. An antenna operating at cryogenic temperatures.

COLIBRIS is a state-of-the-art translation stage (moving trolley) for the Large Space Simulator (LSS) at European Space Agency in Noordwijk. This innovative system will enhance the capabilities of videogrammetry (VG) and thermography (IR) measurement instrumentation during #thermal-vacuum tests.

Struts, rods and beams for a satellite launch vehicle.

This website collects only necessary cookies and analytical cookies; no personal identifiable information will be collected.

By clicking “Accept All Cookies”, you will allow us to gain valuable insights to enhance your user experience and our website.